-

chevron_right

chevron_right

New chip-packaging facility could save TSMC’s Arizona fab from “paperweight” status

news.movim.eu / ArsTechnica · Thursday, 30 November - 19:25 · 1 minute

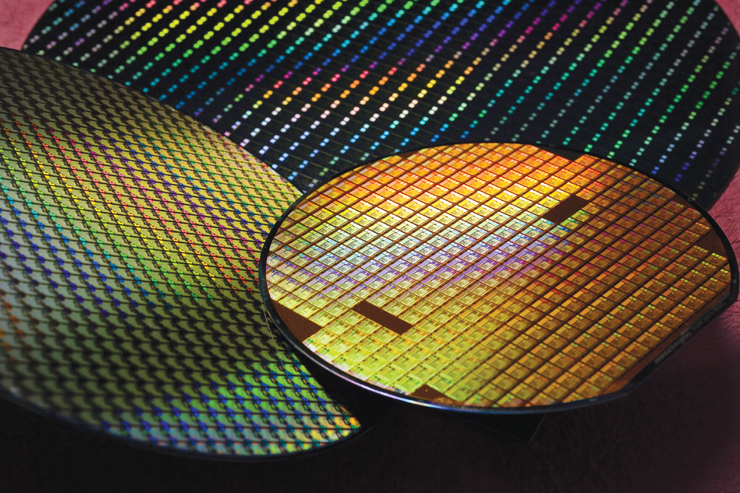

Enlarge / Apple wants to build more of its A- and M-series chips in the United States. (credit: Apple)

Late last year, Apple CEO Tim Cook announced that the company would definitely be buying chips made at Taiwan Semiconductor's new Arizona-based fab once it had opened. Apple working with TSMC isn't new; most, if not all, of the processors currently sold in Apple's products are made on one of TSMC's many manufacturing nodes. But being able to buy them from a US-based facility would be a first.

The issue, as outlined by some TSMC employees speaking to The Information in September , is that the Arizona facility would manufacture chips, but it wouldn't be building a facility to handle packaging. And without packaging, the Arizona factory would essentially be a "paperweight," requiring any chips made there to be shipped to Taiwan for assembly before they could be put in any products.

Today Apple announced that it had solved that particular problem, partnering with a company called Amkor to handle chip packaging in Arizona. Amkor says that it will invest $2 billion to build the facility, which will "employ approximately 2,000 people" and "is targeted to be ready for production within the next two to three years." Apple says that it has already worked with Amkor on chip packaging for "more than a decade."